The automobile engine will come, and then I will consider my life's work complete.

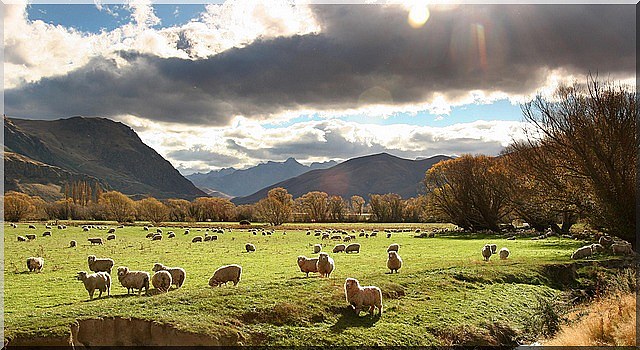

I tend to associate New Zealand with sheep—but clearly I am selling that country short (not that I have anything against sheep). But, I think it is fair to say that one doesn’t automatically associate New Zealand with advanced technology.

Excellence in rugby? Yes. Ferocious Maori war dances (their rugby team, the All Blacks, starts each game with one—a Haka—to intimidate the opposing team)? Absolutely. Extraordinary terrain (as seen in THE LORD OF THE RINGS)? Certainly. But cutting edge engineering innovation? I don’t think so.

That may change. Duke Engines, based in Auckland, have taken the internal combustion engine and re-thought it in the most fundamental way. Best to go to Duke Engines website at www.dukeengines.com to see how the engine works. Most new engines are simply more sophisticated and efficient versions of the status quo. The Duke is a radically new approach to engine design—and it is hard not to be impressed by the sheer originality of the design. It’s awesome.

The result yields the following.

- THERMODYNAMIC EFFICIENCY. The following is a brief extract from a Gizmag piece.

Duke Engines' 3-liter, five cylinder test mule is already making a healthy 215 horsepower and 250 lb-ft of torque at 4,500rpm – slightly outperforming two conventional 3 liter reference engines that weigh nearly 20 percent more and are nearly three times as big for shipping purposes. With an innovative valve-less ported design, the Duke engine appears to be on track to deliver superior performance, higher compression and increased efficiency in an extremely compact and lightweight package with far fewer moving parts than conventional engines. The Duke engine is an axial design, meaning that its five cylinders encircle the drive shaft and run parallel with it. The pistons drive a star-shaped reciprocator, which nutates around the drive shaft, kind of like a spinning coin coming to rest on a table.

- FUEL FLEXIBILITY. The Duke will run on any fuel that ignites with a spark plug.

- MINIMAL VIBRATION. There is a direct relationship between vibration, engine reliability, and passenger comfort. Vibration is destructive and fatiguing. The Duke is nearly vibration free.

- SIMPLICITY. Uses significantly fewer parts. Less costly to manufacture. Easier to maintain. More reliable.

- LIGHTER. Roughly a 20 percent weight saving. That, in itself, yields improved fuel economy.

- MORE COMPACT. The Duke is only about a third of the size of a conventional internal combustion engine.

Automobile manufacturers have invested so much in proprietary engine technologies that it is difficult for an outsider to penetrate that particular marketplace—no matter how innovative. Still, the advantages of the Duke seem overwhelming. It seems to me they are particularly compelling for:

- AVIATION.

- GENERATORS.

- RANGE EXTENSION.

A helicopter is sometimes described as “a flying machine that spends its time trying to vibrate itself to pieces.” There is some truth in that. Vibration is enormously significant where rotary aircraft are concerned—as are space and weight. Apart from passenger fatigue, one consequence is that helicopters are maintenance heavy. They have to be. It’s not good if your engine fails and you are in an aircraft without wings. Its even worse if the Jesus Nut vibrates off. Parts get fatigued as well and have to be replaced on a scheduled preventative basis. Think maintenance hours per flying hour. Expensive.

Personally, I think it is about time we moved towards hybrid-electric use in aviation. Here the Duke would be ideal as the compact, lighter, lower maintenance, low vibration generator.

Where the military are concerned, I see endless applications. Aircraft apart, the Duke would be particularly useful in armored vehicles. Here, the whole idea is have as much space under armor as possible while keeping the overall vehicle as light and compact as you can.

‘Light’ is a relative term where armored vehicles are concerned. They are all heavy. They get even heavier over time because, as anti-armor weaponry improves, extra armor tends to be added. A combat loaded M-113 weighs about 14 tons—substantially more if up-armored. An M1A2 Abrams is about 68 tons. There is no standard weight for up-armoring. It depends what, and how much, you use. Think three to 10 tons as a rough guide..

Anyway, you would be surprised by how heavy and bulky the engines of most armored vehicles are—which means they take up a ridiculous amount of that valuable protected space. A Duke engine powered hybrid electric alternative would increase the space under armor dramatically—while having all kinds of other advantages.

TRADITIONAL M-113 ENGINE – 275 HP - HEAVY, BULKY, NOISY, & VIBRATES. A DUKE HYBRID-ELECTRIC COMBINATION WOULD RESOLVE THESE ISSUES

(ENGINE APART, THE M-113 IS A GREAT VEHICLE & COULD BE EXTENSIVELY UPGRADED AT REASONABALE COST—BUT IT’S MORE FUN TO BUY NEW STUFF)

By the way, you need more space under armor these days not just because soldiers are becoming bulkier (they are) but to accommodate all the electro-optical gear that is now being employed.

The Duke engine is a development worth keeping an eye on. Is it scalable? I see no reason why not.

THE BEST IS YET TO COME. A point to note is that, although far advanced, the Duke is still in development and still being tweaked and refined. Based upon the findings so far, and the normal pattern of such developments, that suggests that there will be further performance improvements—particularly in terms of fuel economy. At present it is made from conventional materials, but it is clear its weight could be further reduced by using lighter alloys.

No comments:

Post a Comment